Surface Functionalization

Functional nano-coatings

Plasma clean

Improved wettability and adhesion

Surface Functionalization

Functional nano-coatings

Plasma clean

Improved wettability and adhesion

Our innovative plasma treatment equipment is trusted globally in both critical industrial manufacturing settings and by leading academics where it is used in biomedical research, life sciences, energy storage, filtration and many other areas of materials science for process improvement.

-

Plasma Technology

What is plasma treatment and what can plasma treatment do?

Plasma treatment can improve the adhesion, wettability, biocompatibility and functionality of various materials. Learn here about how plasma surface treatment and surface energy work and why they are important.

-

Products & Services

Henniker specializes in providing surface engineering solutions that empower industries to achieve enhanced material performance and advanced technological capabilities. With a deep understanding of plasma technology and its applications, we offer a wide range of products and services designed to meet the unique requirements of various sectors. Click the link below to learn more about our products & services.

-

Knowledge Base

We are a leading provider of plasma treatment systems and processes, with a wealth of knowledge and experience in this field. We have prepared a variety of media tools and scientific articles for you to discover more about plasma technology and our products. This will enable you to make informed decisions with confidence and ease. Just click the link below to explore.

Whether it's a batch process or in-line production, prototyping or research facility, we can guide you and advise the best solution. It's likely that we've come across a similar application before, or can point to an existing customer or case study. Ask us, we're here to help.

Listed below is just a small collection of common applications where our plasma treatment technology is used. Please feel free to contact us if your application or material isn't listed.

Plasma treatment can modify the surface properties of polymers without affecting their bulk characteristics. It can be used to improve the biocompatibility and bioactivity of polymeric coatings for medical applications, such as implants, devices, and scaffolds. Plasma treatment can introduce functional groups, increase hydrophilicity, enhance adhesion, and create nanostructures on the polymer surface. These effects can improve the interaction of the polymer with biological tissues, cells, proteins, and drugs. Plasma treatment can also be used to deposit thin layers of biocompatible polymers.

- Modifies surface properties of polymers without affecting bulk characteristics.

- Enhances biocompatibility and bioactivity of polymeric coatings for medical applications.

- Introduces functional groups, increases hydrophilicity, enhances adhesion, and creates nanostructures on the polymer surface.

- Improves interaction with biological tissues, cells, proteins, and drugs.

- Deposits thin layers of biocompatible polymers on inert substrates.

Plasma surface treatment of composite materials, which are used widely in advanced engineering applications, can enhance both cleaning and adhesive bonding of dissimilar materials.

Available treatments can be applied in both batch-plasma and atmospheric in-line plasma cases and often remove the need for primers. We have formed close relationships with major Tier 1 and Tier 2 organisations within the automotive and aerospace industries where our quick turnaround, flexible process development has proved invaluable.

- Treatment of similar & dissimilar materials.

- Replaces tedious surface abrasion steps.

- Increased surface wettability and cleaniliness.

- Better bonding with many adhesives.

- Tailored surface properties, enhanced mechanical properties.

- Environmentally friendly and extends product life span.

Over the past decade, plasma surface treatment has proven to be effective in removing contamination and enhancing wettability of dental prosthetic structures, including implant posts. This treatment plays a crucial role in establishing strong and long-lasting bonds. Enhancing the chemical and physical interaction between dental implants and adhesives is vital for ensuring the sustained success of these implants. Plasma technology offers a solution by effectively eliminating organic contamination and improving the implant surface's wettability.

The plasma activation of dental implants not only enhances wettability but also facilitates the formation of a bioactive surface layer. This bioactivation promotes osseointegration, encouraging the natural integration of the implant with the surrounding bone tissue. By fostering a biologically favorable environment, plasma treatment reduces the risk of inflammatory reactions and increases the long-term success rates of dental prosthetics.

- Plasma activation of dental implants for improved wettability.

- Improving bonding during colouration.

- Fine cleaning of surfaces before veneering and application.

- Encourages natural osseointegration with surrounding bone tissue.

- Streamlined and automated process, requiring minimal operational intervention.

Plasma surface activation of Engineering Polymers, such as PEEK, PTFE and POM, is a reliable and effective technique for increasing print/paint adhesion and bond strength.

Many engineering polymers have characteristically low surface energy and therefore exhibit intrinsically poor adhesion characteristics. The introduction of polar groups from the plasma treatment on the polymer's surface allows for improved wetting and spreading of adhesives, coatings, or printing inks. Consequently, this enhances the contact area between the polymer and the bonding agent, leading to stronger adhesion. Furthermore, the plasma treatment also removes any contaminants or oxidation products that might be present on the surface, providing a clean and activated substrate for bonding.

- Small scale in-line treatment and industrial sized vacuum chamber treatments available

- Improved bonding of paint and printed inks to polymer surface

- Specific surface functionality without affecting bulk properties

- Hydrophobic, oleophobic and hydrophilic properties are possible

Electric Vehicle (EV) technology is rapidly advancing, revolutionising the motor industry and contributing to a cleaner and sustainable future. At the heart of every electric vehicle lies the battery, which is crucial for its performance and range. To improve the efficiency, lifespan, and overall performance of EV batteries, manufacturers are turning to innovative solutions like plasma treatment. Plasma treatment technology offers several advantages in enhancing EV battery production.

Plasma treaments can be used to enhance electrode performance. It is possible to modify the electrode's surface characteristics to improve surface energy, or to alter its morphology and even it's chemical composition. These modifications enhance the electrode's ability to store and release energy, leading to improved overall efficiency, stability and reducing the risk of delamination or degradation.

Plasma technology can also be used to extend the battery lifespan, by removing impurtities, contamination and unwanted materials, treatments can enhance the structural integrity and and prevent formation of detrimental byproducts. This reduces the risk of capacity loss, electrode degradation, and premature battery failure.

- Improved electrode performance, leading to increased battery capacity, faster charging times, and enhanced overall efficiency.

- Extended battery lifespan by preventing capacity loss, electrode degradation, and premature failure.

- Enhanced structural integrity and stability of battery components.

- Optimization of adhesion between active materials and electrode substrates.

- Reduction of impurities, contaminants, and unwanted materials in battery components.

One of the most common problems in stable isotopic measurements is the presence of hydrocarbon (e.g. bitumen) and adhering organic material. Effective removal of this hydrocarbon material needs to be accomplished by a method that in turn does not itself also alter the initial isotopic composition.

When wet chemical methods are applied isotopic composition can be compromised whereas with oxygen plasma cleaning/ashing can ensure that this initial isotopic composition is retained.

Preparation is challenging since the composition can easily break during the cleaning process, resulting in a loss of material for analysis. The plasma cleaning/ashing method can remove stubborn organic materials without affecting the sample material of the sample, resulting in a clean material for analysis using mass spectrometry.

- Removal of stubbon organic contamination

- No loss of analytical material

- Effective alternative to wet chemical methods

Plasma surface functionalization/coating is one of the most exciting areas of plasma technology. It involves breaking the top-most surface bonds of a material and terminating them with new chemical functionalities which impart an entirely new surface characteristic without affecting the bulk properties of the material.

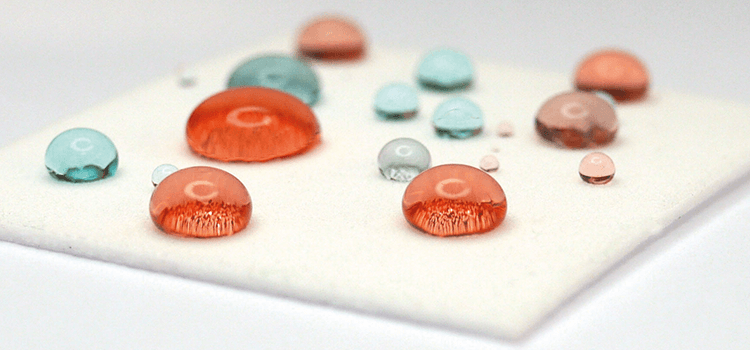

Liquid repellent (Hydrophobic) plasma coatings are a sub-category of plasma surface functionalization, the specific precursor being chosen to produce a permanent, low surface energy layer on the material or part being treated. The hydrophobic surface is typically less than 1/100th thickness of a human hair, colourless, odourless and doesn’t affect the look or feel of the material in any way.

Permanent hydrophobic surfaces are rapidly finding new applications all the time. Liquid repellent coatings currently enhance products in the textile, medical device, ophthalmic and consumer electronics industries to name but a few.

- Improve material resisitance to wear, abrasion and reduce chemical exposure.

- Plasma treatment offers exceptional control over surface properties and ensures precise and uniform coating application

- Enhance productivity, coated surfaces requires less cleaning, reducing downtime and increasing efficiency.

- Hydrophobic coatings repel liquids, oils, and contaminants.

- Tailored liquid repellent coatings to meet specific requirements.

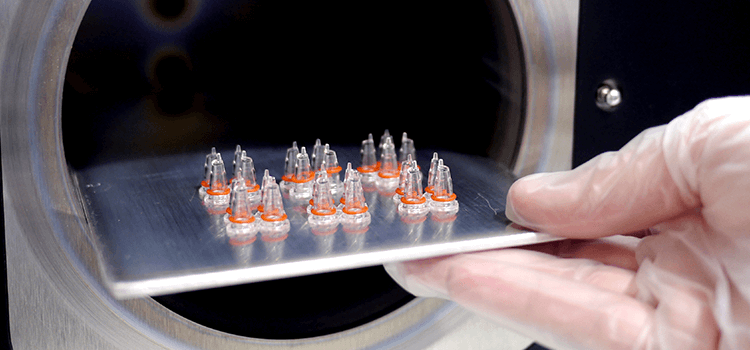

Plasma treatment of medical devices is used to increase the wettability of high-performance polymers which can be particularly difficult to print on and bond to due to their inherent low surface energy.

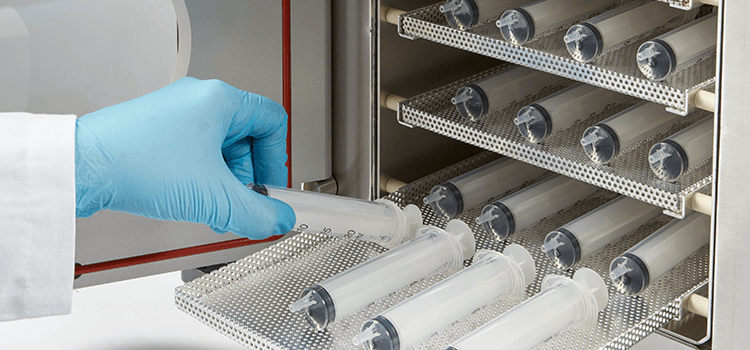

Plasma surface activation is also used to increase adhesion for balloon catheters prior to gluing, syringes/hubs prior to gluing and to treat intra-ocular lenses prior to biocompatible coatings or to make them hydrophilic. Henniker have very highly trained staff to deal with all your requirements and are extremely experienced in the plasma treatment of medical devices, having worked with and retained many clients across the medical device field.

- Plasma surface activation to increase adhesion for balloon catheters prior to gluing

- Plasma surface activation of syringes/hubs prior to gluing

- Treatment of intra-ocular lenses prior to bio-compatible coatings or to make them hydrophilic

- Plasma coatings for functionalisation of immuno assays and cell culture media

- Ultra-fine cleaning of medical implants

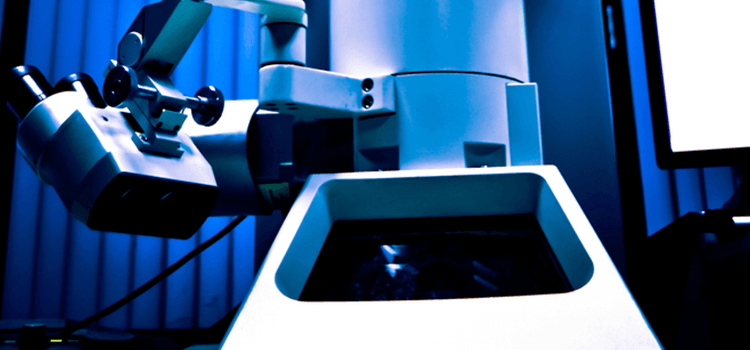

Our low-cost plasma cleaners/plasma ashers for electron microscopy users are designed specifically for fast and efficient cleaning of sample holders and individual grids and stubs.

The TEM range for electron microscopy are fully automated bench-top plasma cleaners that come with standard adapters which are suitable for the sample holders supplied with all the major microscope manufacturers. The plasma output power is fully variable over the range 0-100W, resulting in a very controllable & gentle cleaning process. Common sources of error inside the microscope are clearly reduced with plasma cleaning and the dwell time during the measurement is significantly increased.

- Fully variable plasma output between 0-100W.

- Very low power setting as standard.

- Adapters for common SEM sample holders.

- Compact laboratory size bench-top instrument.

- Operation with a range of cleaning gases.

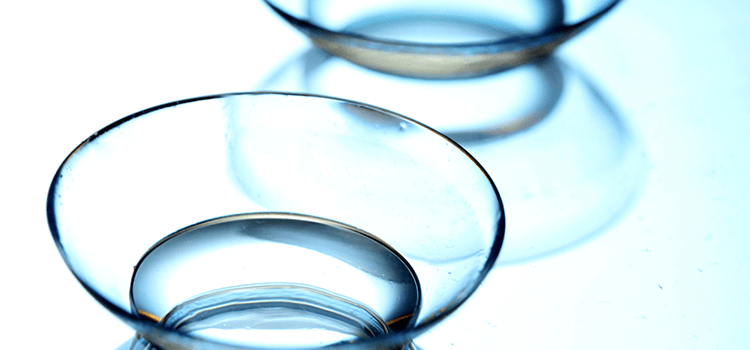

Plasma cleaning of contact lenses and other optics produces hyper-clean surfaces by removing the thin layer of organic contamination that is present on almost all surfaces. Organic contamination which may be present on all lens surfaces is typically only a few nanometres thick but it is sufficient to alter optical properties. Plasma cleaning of optics & lenses is performed with oxygen gas, or sometimes even lab air is sufficient, in a few 10’s of seconds and with no chemical waste. Unlike solvent cleaners, plasma cleaning leaves absolutely no residue.

Plasma cleaning of gas permeable contact lenses is now widely used to improve surface wettability characteristics which result in increased comfort for longer and also inhibits deposits. The effects of the plasma can last for many weeks.

- Plasma cleaning improves wettability of gas permeable contact lenses

- Increases patient comfort

- Plasma cleaning removes trace organic contamination from other optics

- Surfaces are rendered more hydrophilic

Plasma surface functionalization/coating is one of the most exciting areas of plasma technology. It involves breaking the top-most surface bonds of a material and terminating them with new chemical functionalities which impart an entirely new surface characteristic without affecting the bulk properties of the material.

Permanently wettable or 'Hydrophilic' plasma coatings are a sub-category of plasma surface functionalization, the specific precursor being chosen to produce a permanent, high surface energy layer on the material or part being treated. The hydrophilic surface is typically less than 1/100th thickness of a human hair, colourless, odourless and doesn’t affect the look or feel of the material in any way.

Permanent hydrophilic surfaces are employed for example in microfluidic devices to improve fluid flow and in many examples of life science for protective coatings, barrier layers and to improve biomolecular absorption.

- Improve material adhesion to glue, paint, printing ink and bioactivity.

- Plasma treatment offers exceptional control over surface properties and ensures precise and uniform coating application.

- Enhance productivity, coated surfaces requires less chemical treatments, reducing costs and increasing efficiency.

- Hydrophilic coatings attract liquids improving wetting and spreading behaviours.

- Tailored hydrophilicity to meet specific requirements.

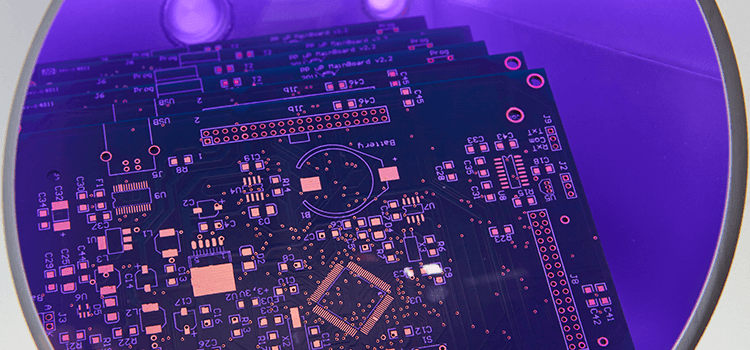

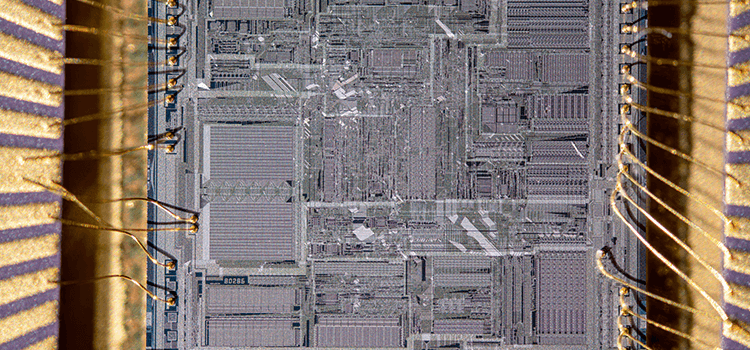

Plasma cleaning is a dry & environmental friendly technique answering the needs of the printed circuit board (PCB) and electronic component assembly industry. It is a well-established technique for removing residue (desmearing) left behind by laser drilling of vias.

Established PCB Manufacture can incorporate our user friendly & cost-effective cleaning processes easily and efficiently. Our plasma cleaning machines feature multiple loading racks that ensure excellent uniformity across the PCB, between PCBs and from process to process.

- Plasma Cleaning of PCB’s prior to bonding

- Plasma Activation of printed circuit boards prior to potting & encapsulation

- Etching & desmearing of epoxy, flex-rigid and Teflon printed circuit boards

- De-oxidation of gold contacts

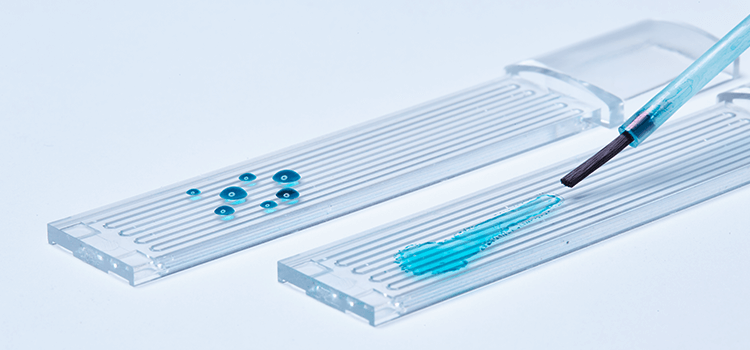

Plasma treatment of PDMS in microfluidic fabrication produces a permanent and irreversible bond between PDMS and glass, improving analyte flow within microfluidic channels.

PDMS (Polydimethylsiloxane) is by far the most popular material used in microfluidics research where it is deployed for rapid prototyping with minimal cost. PDMS, however, requires a surface treatment step in order to produce strong, conformal bonds between surfaces. Plasma treatment of PDMS increases hydophilic (-OH) groups on the PDMS surface which subsequently form strong covalent bonds (Si– O–Si) when brought together with glass. These covalent bonds form the basis of a practically inseparable seal between the layers.

- Removal of hydrocarbon groups.

- Exposure of hydrophilic -OH groups.

- Improved bonding to PDMS and glass substrates.

- Improve analyte flow.

- Possibility of patterned surfaces with alternating hydrophilic/hydrophobic regions.

- Plasma treatment for lab-on-a-chip fabrication of microfluidics.

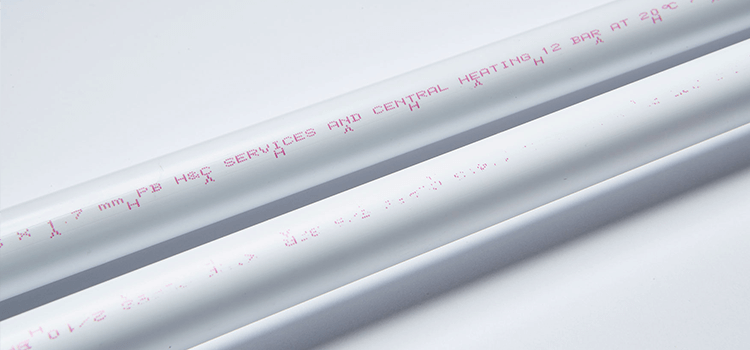

Plasma treatment of plastics to improve adhesion is a two-fold surface activation and cleaning process.

In the first instance, the plasma treating the plastic cleans away volatile organic compounds that otherwise impede bonding, painting and gluing. Secondly, plasma surface activation creates a hydrophilic surface which is totally wettable to adhesives, paint, lacquers etc. The bonds formed are extremely strong so that adhesions onto plasma-treated surfaces are extremely durable. On many materials, the treatment can last for several months if stored in a dust-free environment.

- Increase surface wettability

- Improve printing and bonding characteristics

- Low friction plasma coatings on seals and o-rings

Plasma surface activation of materials prior to gluing, painting and printing is one of the most common uses of plasma. The inherently 'cold' plasma process allows temperature-sensitive mateirla to be treated as equally well as metals, glass and ceramics.

In each case the action of the plasma is two-fold; removal of organic contamination from the surface followed by increased wettability of the surface. Plasma processing does not affect the bulk properties of a material in any way. The increased surface energy results in a significantly stronger bond of most materials with many adhesives, paints and printing inks. We also offer a wide range of surface test methods for comparison of preand post-plasma treated parts.

- Plasma removes organic contamination from the surface.

- Plasma surface activation makes the surface more wettable.

- Typically 2-fold to a 10-fold improvement in lap-shear strength and peel-strength.

- Adhesion to polymers, glass, ceramics and metal are all improved.

- Treatment of complex 3D objects.

- Localized plasma treatment without masking replaces surface abrasion pre-treatments.

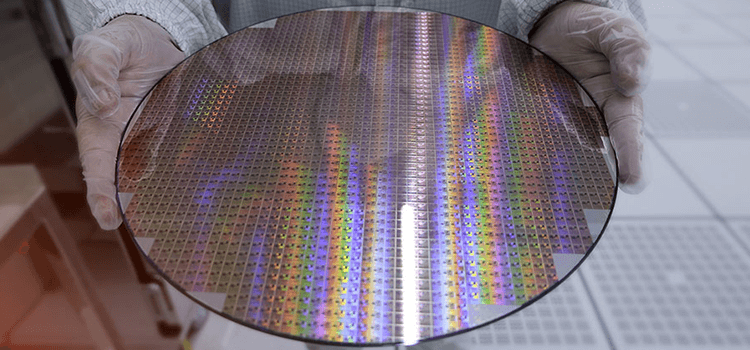

Spin coating has been widely used for several decades in photolithography, to deposit photoresist on silicon wafers, and the scope has been extended in recent years to chemically engineering the interface of support and solution to obtain specific structural order in the deposited thin films.

Several important factors influence film deposition, including viscosity of the deposited solution and spin speed for example. Surface wettability also plays an important role and can be controlled with routine plasma cleaning of the substrate prior to deposition. Henniker’s bench-top plasma systems are widely used for this purpose to achieve clean, contamination free substrates prior to spin coating.

- Achieve clean contamination-free substrates prior to spin coating

- Controlled surface wettability before substrate deposition

- Reduce defects and increase film quality

- Save time and improve cost efficiency without expensive chemical treatments or complex equipment.

Plasma cleaning utilizes oxygen, argon, hydrogen, or mixtures of these gases. Combinations of these gases are suitable for nearly every case, however there are considerations such as the dulling of lead-frames (in wire bonding applications) when using oxygen, or the re-deposition of metal particles in the case of argon, as well as safety concerns when using hydrogen. Henniker have developed a simple, low-cost alternative method based on plasmas generated using water vapor, which effectively removes contamination and reduces oxide layers without any potential drawbacks.

Overall, water vapor plasma treatment offers numerous advantages, including non-toxicity, surface cleaning and decontamination, improved adhesion, surface modification, sterilization and disinfection capabilities, energy efficiency, cost-effectiveness, and versatility. Its unique properties make it a promising technology with diverse applications across different fields.

- Non-toxic and eco friendly

- Surface cleaning and decontamination

- Versatile and easy to implement

Plasma cleaning prior to wire bonding efficiently removes organic contaminants and thin oxide layers under high throughput conditions, quickly, efficiently and reproducibly, greatly enhancing yield and reducing bond failures.

In many electronics application areas, there is a stringent requirement for ultra-clean bond pads prior to wire bonding. This is especially true in e.g. semiconductor and space satellite instrumentation fabrication. Wire bond pad contamination results in poor bond pull strength and also bond strength uniformity. Plasma cleaning may be applied as an in-line solution e.g. prior to encapsulation, or as a batch processing step with bespoke frame loading arrangements and completely removes any surface contamination.

- Custom lead frame loading arrangements.

- Plasma cleaning with single gases and gas mixtures.

- Increased bond pull strength.

- Wide range of plasma cleaner chamber sizes.